Cement

For the cement industry GINO-AKA liquid starters are the primary choice for customers all over the globe. The equipment is subject to harsh environments and must be durable, reliable and cost efficient. With our AK liquid starter we designed a LRS meeting all requirements of the cement markets.

Floatglass

For the production of Floatglass the GINO-AKA AKGRAD32 power controller is used for precise electrical heating processes. The use of the AKGRAD power controller significantly reduces carbon emissions and energy consumption of the glass furnaces.

See products »

Mining

The mining industry requires specific performances from liquid resistance starters. Large scale automation with applications that require up to 20MW power are a regular sight at Gold, Copper, Zink or Bauxite operations. With the MAK starters GINO-AKA provides a specially designed LRS to meet the customers highest performance expectations

Industrial Heating

Modern heating processes shift towards electrical heating instead of gas or fuel burning. This has environmental as well as economical reasons. In order to precisely manage heating processes in the industrial environments we provide individual thyristor based power controllers.

See products »

Sugar

For the production of sugar GINO-AKA supplies liquid starters and slip resistors for the cane shredders. Depending on the shredded materials there is special requirements towards the starters and slip resistors. GINO-AKA specially engineers solutions to meet the demands.

Steel

Steel production requires a significant amount of energy. Some steel furnaces can be operated electrically. For electrical steel furnaces high current power controllers can be used for heat regulation and reduction of overall energy consumption.

See products »

Quarries

GINO-AKA liquid starters are used in quarries to crush limestone or other building materials. The crushers require high torque and reliable, heavy duty technology. GINO-AKA provides the dependable ARL and Vectrohm starters with advantageous pricing for motor powers up to 500kW

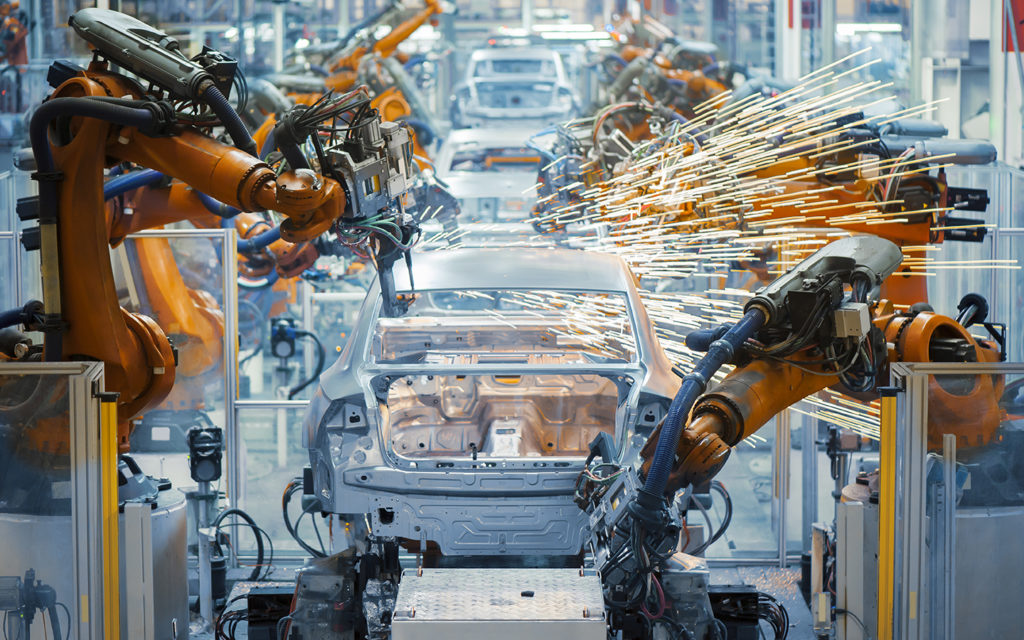

Automotive

In the manufacturing of automotive vehicles very precise heat treatment is required in some steps of the production line. This applies for example for the controlled treatment of paint layers. For these applications we provide precise low power heat zone controllers.